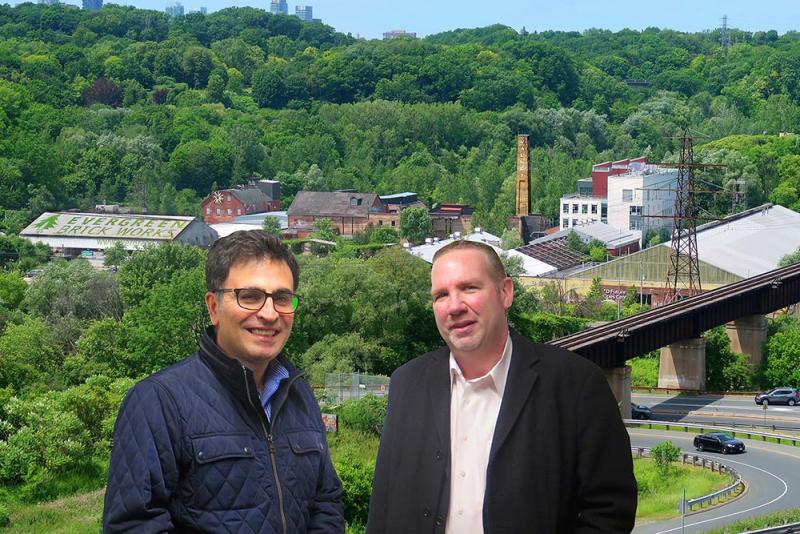

Evergreen Brickworks

Future City leaders show how geothermal works for institutional property

The Don Valley Brick Works dates back to 1882 when homesteader William Taylor discovered red clay and shale while putting up a fence on a formerly glacial floodplain at the intersection of the Don River and Mud Creek in Toronto. He and his brother created the brickworks in 1889, and after a horrific downtown fire in 1904, a bylaw prohibited wood as the primary material for new buildings in the city. The Don Valley Brick Works flourished for nearly 100 years, finally closing when the clay ran out in 1984.

In the late 1980s the site was expropriated by the city and designated a heritage site and its more than a dozen buildings eventually placed under the stewardship of Evergreen, which had led development of the Weston Family Quarry Garden at the north end. It was not until the turn of the century that Evergreen could begin building rehabilitation in earnest, so for several years young partyers, valley transients, and animals had the run of the place. Many surfaces became covered in graffiti, and although the buildings have all been modernized now, the brick ovens and the graffiti remain intact, because they were both deemed heritage elements that should be preserved.

The Evergreen Brickworks is now a fascinating complex, however, the heritage designation along with the inherent characteristics of the buildings created significant challenges for the design team, in particular Ali Anvari, Facilities Director, who oversaw many of the improvements. “We decided early that the buildings should become carbon neutral, but we could only get permission for three inches of insulation on the roof plus a vapour barrier and membrane.”

He is talking about the biggest structure (53,000 square feet), which is built like a huge barn with air stratification challenges. “We wanted to avoid gas heating and the best option was geothermal, but we had a small slip of ground area on the east side in which we would be allowed to install a geofield,” says Anvari. “But we finally found Geosource Energy who said ‘no problem we can do it with vertical angled drilling, under the building.’ They were able to install 40 boreholes about 600 feet deep.”

“We were excited to work with Evergreen, Ellis Don, and Brookfield Global on this showcase project,” says Paul Frith, Sales Director for Geosource Energy in Caledonia. “We brought in a special new rig, that got the job done. It was great to work with an innovative project team because our company is innovative too.”

“We are risk-takers,” says Anvari. “It positions us to combine different technologies in innovative ways. We call ourselves a living lab because we have various examples of experimental solutions on the site. So far everything is working!”

The site now includes event space, indoor and outdoor fun areas for families, historical installations, shops, cafes, and one of the biggest farmers’ markets in the city. The next step is to install 275 solar thermal panels on the roof, which will supplement the geothermal plant. This will allow conditioning of more of the Brickworks buildings, especially the second biggest one, which is currently still heated by gas boilers. The boilers will soon become a seldom-used emergency backup system.

The team is also looking at solar photovoltaic and electricity storage to further reduce the footprint and operating costs of the complex. Evergreen is now responsible for the Future Cities Canada project, a national collaborative of top foundations with a mandate to accelerate inclusive innovation in our cities. Says Anvari: “In the near future geothermal and some of the other innovative solutions at the Evergreen Brickworks will be common elements in most of Canada’s buildings.”